Student Author: Matthew Preisser

Co-Author: Brendan Higgins

Millions of pounds of food waste are generated in the United States every year, and Auburn is no exception. This food waste burdens the environment by contributing to pollution associated with landfills and is an inefficient use of natural and economic resources. Alabama alone produces over 1.5 million pounds of poultry litter per year. Poultry litter contains harmful bacteria (e.g., salmonella) and high concentrations of nutrients that can contribute to water pollution. Currently, most of this litter is applied on the surface, but concerns about nutrient build-up in soils may soon limit this practice. A possible solution to divert poultry litter and other forms of food waste from the landfill is through the anaerobic digestion process. Anaerobic digestion has the potential to divert food waste and convert it into methane-rich biogas that can be used as a heat and electricity source.

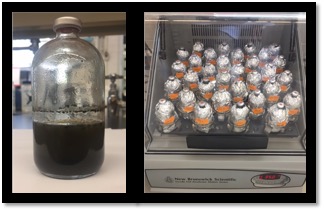

The objective of this research project was to determine if locally sourced poultry litter and food waste are viable feedstocks for anaerobic digestion at Auburn University. It was hypothesized that both locally sourced poultry litter and food waste from on campus dining venues (the Village Dining) could produce biogas with high concentrations of methane, which can be used to generate heat. To test this, 160 mL batch reactors were loaded with varying amounts of inoculum containing methane-producing bacteria, water, and waste. They were then left in an incubator at 35oC for close to a month (Figures 1). Pressure readings were taken every two days to measure the gas buildup inside the reactors. In reactors loaded with a 1:1 ratio of waste to inoculum by volatile solids, a bio-methane potential (BMP) of 80.8 mL-CH4/gram of food waste and 183.5 mL-CH4/gram of poultry litter was achieved.

Through this research project, it was determined that a more efficient way to measure biogas production, other than measuring pressure changes, was needed in the laboratory. This is because the build-up of biogas (the metabolic end-points) in the headspace can inhibit further digestion. A more suitable approach is to allow biogas to leave the reactor while measuring its flow rate. A low-flow gas measurement device that monitors water displacement over time was consequently constructed. This device uses a time of flight (ToF) infrared ranging sensor and Arduino, a commercially available microprocessor, to monitor six different bioreactors at a single time. A Matlab™ code was also developed to be able to convert water displacement into a volumetric flow rate. Future students in the lab will be able to calibrate this device and use it to monitor larger scale reactors.

Moving forward, there is a desire to use the anaerobic digestion process in conjunction with food waste generated by TigerDining. A closed-loop food cycle that converts uneaten and wasted food into heat for greenhouses on campus has the potential to reduce Auburn University’s natural gas needs. The application of this technology can have a direct impact on Auburn University’s energy needs.

Statement of Research Advisor: Matt has carried out a project on anaerobic digestion of poultry litter and food waste in satisfaction of the requirements of his Undergraduate Research Fellowship. This research holds the potential to advance the conversion of waste materials into renewable energy and organic fertilizer. Closer to home, Matt’s project can have a transformative impact on food waste management practices at TigerDining on the AU campus. His results and development of a gas monitoring system have laid the groundwork for testing of fed-batch reactors operated over a long-time horizon. —Brendan Higgins, Biosystems Engineering

Figure 1: 160 mL bioreactor containing inoculum, waste, and water (left) placed in an incubator at 35oC (right).

Last Modified: